Difference between revisions of "Southbend Lathe"

m |

|||

| (33 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

[[File:SouthbendLathe.jpg|400px|thumb]] | |||

=About our machine= | |||

*Model: 8113C | |||

*Bed length: 6 feet | |||

*Swing: 13 inches | |||

*Spindle thread: 1 7/8" - 8 | |||

*Spindle bore: 1 1/8" | |||

*Tool post: Aloris BXA (200 series) compatible | |||

==Accessories== | |||

*[https://www.youtube.com/watch?v=wCDdxtjdg8Y Taper attachment] (missing some pieces) | |||

*Steady Rest | |||

*Follower Rest | |||

*ER16 Collet adapter | |||

=User Guide= | |||

==Safety== | |||

*'''NEVER LEAVE THE CHUCK KEY IN THE HEADSTOCK, EVEN FOR A SECOND.''' It can become a deadly projectile if you turn on the lathe with it in there. | |||

*'''Do not reach over the headstock when turning on the lathe.''' Reach with your right arm instead. Nobody wants to get caught in a machine capable of carving hardened steel. | |||

*'''Make sure work is secured before turning on the lathe.''' While it's not moving, try to wiggle the piece in the chuck. If it moves at all, check your setup for problems. | |||

*'''Ensure work and headstock will not collide with any part of the machine.''' With the power off, spin the chuck by hand to check this. | |||

*'''Use sharp tools!''' Dull tools can catch the work and break the tool or the lathe itself. | |||

== | ==Lubrication and Upkeep== | ||

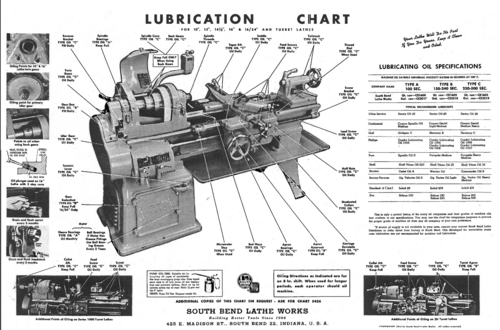

[[File:southbend-lubrication.png|500px|thumb]] | |||

Oil Types: | |||

*Type A - Spindle Oil | |||

*Type B - Way Oil | |||

*Type C - Gear oil | |||

Lubricate every time: | |||

*Spindle - Spindle Oil | |||

*Ways - Way Oil (thin coating) | |||

Lubricate every 1-2 weeks | |||

*Gearbox - Gear Oil | |||

After | Clean every time | ||

**Inside and outside of collets before using | |||

**Inside chuck jaws before inserting material | |||

**After work - clean chips off of machine using brush and pan | |||

**Empty out chip pan below ways | |||

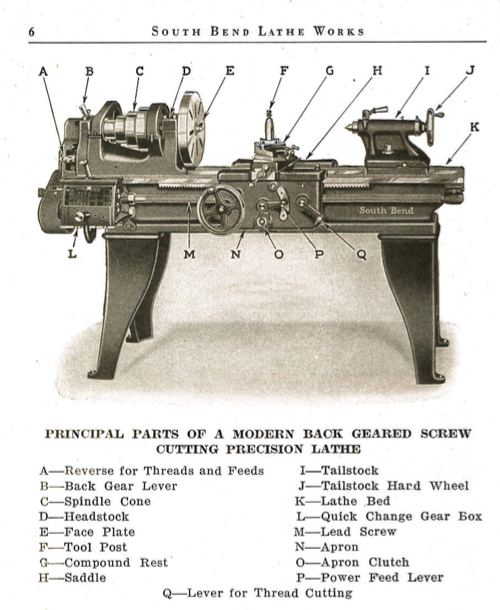

== | ==Controls== | ||

[[File:southbend-diagram.png|500px|thumb]] | |||

==Changing the chuck== | |||

There are 3 chucks that we have: a 3-jaw, 4-jaw, and 6-jaw. There are internal and external jaws available for the 3-jaw and 4-jaw. | |||

To change the chuck, you will need 2 things: | |||

*A scrap board to sit across the ways underneath the chuck | |||

*A 3ft or so 2x4 or similar piece of lumber | |||

Follow these instructions to remove the chuck and thread the new one on: | |||

#Lay the scrap board across the ways. This will prevent the chuck from falling once unthreaded and crashing against the ways, as well as give it a landing pad so you don't have to hold the weight for very long | |||

#Open the jaws enough to grip the 2x4, and lock them down on it. For a 3 jaw, this will be awkward. | |||

#Lock the back gears and lock the spindle to the pulleys, freezing the movement of the spindle. | |||

#Attempt to loosen the chuck by applying force to the 2x4. Use swift and repeated movements to try to "walk" the threads loose. | |||

#Once the chuck is loose, unthread it slowly until it is about off the threads, then prepare to gently lower it onto the scrap board | |||

#Once chuck is completely off, clean and oil the threads on the spindle and inside the chuck. This will keep the surfaces clean and rust-free, which will help the chucks remove easily. | |||

#Store the unused chuck under the lathe, covering it with a rag or plastic to keep it clean and prevent chips from getting in it. | |||

#Take your new chuck and inspect the threads. Clean them with a rag and oil them. | |||

#Thread the new chuck on. When it is close to being threaded all the way, take the chuck and spin it hard so when it gets to the end it locks it in. | |||

#Disengage the back gearing or the locking pin for the pulleys so the spindle is no longer locked. | |||

#You're all done! | |||

Note: Do not use excessive force right away when removing the chuck. This method of removal has potential to damage the gearing in the lathe, so if there is a lot of trouble get some help before breaking the machine. | |||

==Changing the speeds== | |||

Moving the belt on the pulleys: | |||

#Lift up the lid on the headstock behind the chuck. You should see a speed chart on the inside of the lid. | |||

#Open the cabinet below the headstock where the motor is. | |||

#Rotate the lever by the cabinet door clockwise until it is at the top of the rotation (or to put it another way: at 12 o' clock). This will raise the motor so it is no longer putting tension on the belt. | |||

#You can now freely move the belt to the position you want. Make sure it is aligned top and bottom, do not try to run the belt diagonally. | |||

#Once in position, rotate the handle counter-clockwise to lower the motor back down. Make sure it is all the way down. Check your belt again to make sure it's aligned well. | |||

#Close up the cabinet, and close the lid. You're all done! | |||

Going from Low to High: | |||

#Disengage the back gearing using the lever towards the back of the headstock on the left side. | |||

#Open the lid to the headstock, and the small cover on the side of the headstock near the chuck. | |||

#Rotate the chuck until you see the locking pin come into view where you lifted the small cover. | |||

#Grab the pin, and pull out and up. While doing that, rotate the pulleys until you feel the pin slide up and lock into the pulleys. | |||

#Close the lids. You're all done! (Double-check that the chuck rotates with the pulleys as expected. If it is hard to turn, make sure the back gears are disengaged) | |||

Going from High to Low: | |||

#Open the lid to the headstock and the small cover on the side of the headstock near the chuck. | |||

#Rotate the chuck until you see the locking pin come into view where you lifted the small cover. | |||

#Grab the pin and pull it out and down. The chuck and pulleys should now be disengaged from each other. | |||

#Engage the back gearing using the lever towards the back of the headstock on the left side. | |||

#Close the lids. You're all done! | |||

==Aligning the tailstock== | |||

==Using the powerfeed and gearbox== | |||

== | ==Using the halfnut and threading dial== | ||

=Manuals= | |||

[https://drive.google.com/open?id=1LMAbFnK7X79luoh62wrIVlhS_DbI3yoC How to Run a Lathe] - an old handbook with everything you need to know | |||

[https://drive.google.com/open?id=1KzXk2M5TSDhB24aFMRvnIBo5W2zFEN18 Southbend] -folder on the member google drive full of related documents | |||

=Helpful Videos= | |||

*[https://youtu.be/gIH6SAXWR5A Southbend Lathe Training Video] | |||

*[https://www.youtube.com/watch?v=Za0t2Rfjewg Essential Machining Skills: Working with a Lathe] | |||

*[https://www.youtube.com/watch?v=wCDdxtjdg8Y Taper Attachment assembly] | |||

*[https://www.youtube.com/watch?v=ctxkVToGHAA Disassembly and explanation of the saddle, half-nut, and power feed] | |||

*Grinding HSS tools | |||

*Using dial indicators | |||

*Using calipers and micrometers | |||

*[https://www.youtube.com/watch?v=BAD10CKG4Gw Mini machinist mallet] - video of a mallet lathe project (warning: sick metal music playing the whole time) | |||

=Stock materials= | |||

Important factors (machinability, hardness, material and cutter, maximum sizes) | Important factors (machinability, hardness, material and cutter, maximum sizes) | ||

| Line 68: | Line 125: | ||

Cast | Cast | ||

=Beginner Projects= | |||

*[https://www.patreon.com/posts/14548892 Machinist's Hammer] - a project by Tim Nummy | |||

*[https://www.youtube.com/watch?v=KcAk_Lec_hc Whistle] | |||

*[https://www.youtube.com/watch?v=-dyO4PEkEkc Storage Tube with hidden seam] | |||

*[https://www.youtube.com/watch?v=gFQx70JAixo Spinning Top] | |||

*[https://www.youtube.com/watch?v=t9NGty1CVII Decorative Ring] | |||

*[https://www.youtube.com/watch?v=c0xcyI0hZOI Machinist Jack] | |||

*[https://www.youtube.com/watch?v=5-33oi0Wua8 Chuck key] | |||

=Tool bits and accessories= | |||

* Aloris BXA-style (200 series) quick-change toolpost with multiple tool holders | |||

==What we have for insert tool holders== | |||

*SHARS 1/2 X 4" RH MCLN INDEXABLE TURNING TOOL HOLDER CNMG | |||

*MGEHR1616 Parting Off Turning Tool Holder | |||

**Insert: MGMN200 | |||

*Anytime Tools 5 Piece 1/2" MINI LATHE INDEXABLE CARBIDE INSERT TOOL BIT SET - [https://www.amazon.com/gp/product/B0087RGCGO/ link] | |||

**Insert: TCMT 090204 - [https://www.amazon.com/dp/B00SDYYI5I link] | |||

==Where to buy== | |||

*[https://alexnld.com/product-category/home-garden/business-industrial/manufacturing-amp-metalworking/metalworking-tooling/toolholding/page/2/ AlexNLD - Toolholding] - Inserts, tool holders, and more. | |||

*[https://www.mscdirect.com/browse/Tool-Holding MSC Direct - Tool Holding] | |||

*[https://www.mcmaster.com McMaster Carr] - Everything, but also inserts and tool holders | |||

*[http://ebay.com Ebay] - Good ol' ebay, its got everything | |||

*[http://amazon.com Amazon] - Amazon also has everything | |||

[[Category: Tool]] | |||

[[Category: Machine Shop]] | |||

[[Category: Safety Checkout]] | |||

Latest revision as of 09:50, 3 July 2024

About our machine

- Model: 8113C

- Bed length: 6 feet

- Swing: 13 inches

- Spindle thread: 1 7/8" - 8

- Spindle bore: 1 1/8"

- Tool post: Aloris BXA (200 series) compatible

Accessories

- Taper attachment (missing some pieces)

- Steady Rest

- Follower Rest

- ER16 Collet adapter

User Guide

Safety

- NEVER LEAVE THE CHUCK KEY IN THE HEADSTOCK, EVEN FOR A SECOND. It can become a deadly projectile if you turn on the lathe with it in there.

- Do not reach over the headstock when turning on the lathe. Reach with your right arm instead. Nobody wants to get caught in a machine capable of carving hardened steel.

- Make sure work is secured before turning on the lathe. While it's not moving, try to wiggle the piece in the chuck. If it moves at all, check your setup for problems.

- Ensure work and headstock will not collide with any part of the machine. With the power off, spin the chuck by hand to check this.

- Use sharp tools! Dull tools can catch the work and break the tool or the lathe itself.

Lubrication and Upkeep

Oil Types:

- Type A - Spindle Oil

- Type B - Way Oil

- Type C - Gear oil

Lubricate every time:

- Spindle - Spindle Oil

- Ways - Way Oil (thin coating)

Lubricate every 1-2 weeks

- Gearbox - Gear Oil

Clean every time

- Inside and outside of collets before using

- Inside chuck jaws before inserting material

- After work - clean chips off of machine using brush and pan

- Empty out chip pan below ways

Controls

Changing the chuck

There are 3 chucks that we have: a 3-jaw, 4-jaw, and 6-jaw. There are internal and external jaws available for the 3-jaw and 4-jaw.

To change the chuck, you will need 2 things:

- A scrap board to sit across the ways underneath the chuck

- A 3ft or so 2x4 or similar piece of lumber

Follow these instructions to remove the chuck and thread the new one on:

- Lay the scrap board across the ways. This will prevent the chuck from falling once unthreaded and crashing against the ways, as well as give it a landing pad so you don't have to hold the weight for very long

- Open the jaws enough to grip the 2x4, and lock them down on it. For a 3 jaw, this will be awkward.

- Lock the back gears and lock the spindle to the pulleys, freezing the movement of the spindle.

- Attempt to loosen the chuck by applying force to the 2x4. Use swift and repeated movements to try to "walk" the threads loose.

- Once the chuck is loose, unthread it slowly until it is about off the threads, then prepare to gently lower it onto the scrap board

- Once chuck is completely off, clean and oil the threads on the spindle and inside the chuck. This will keep the surfaces clean and rust-free, which will help the chucks remove easily.

- Store the unused chuck under the lathe, covering it with a rag or plastic to keep it clean and prevent chips from getting in it.

- Take your new chuck and inspect the threads. Clean them with a rag and oil them.

- Thread the new chuck on. When it is close to being threaded all the way, take the chuck and spin it hard so when it gets to the end it locks it in.

- Disengage the back gearing or the locking pin for the pulleys so the spindle is no longer locked.

- You're all done!

Note: Do not use excessive force right away when removing the chuck. This method of removal has potential to damage the gearing in the lathe, so if there is a lot of trouble get some help before breaking the machine.

Changing the speeds

Moving the belt on the pulleys:

- Lift up the lid on the headstock behind the chuck. You should see a speed chart on the inside of the lid.

- Open the cabinet below the headstock where the motor is.

- Rotate the lever by the cabinet door clockwise until it is at the top of the rotation (or to put it another way: at 12 o' clock). This will raise the motor so it is no longer putting tension on the belt.

- You can now freely move the belt to the position you want. Make sure it is aligned top and bottom, do not try to run the belt diagonally.

- Once in position, rotate the handle counter-clockwise to lower the motor back down. Make sure it is all the way down. Check your belt again to make sure it's aligned well.

- Close up the cabinet, and close the lid. You're all done!

Going from Low to High:

- Disengage the back gearing using the lever towards the back of the headstock on the left side.

- Open the lid to the headstock, and the small cover on the side of the headstock near the chuck.

- Rotate the chuck until you see the locking pin come into view where you lifted the small cover.

- Grab the pin, and pull out and up. While doing that, rotate the pulleys until you feel the pin slide up and lock into the pulleys.

- Close the lids. You're all done! (Double-check that the chuck rotates with the pulleys as expected. If it is hard to turn, make sure the back gears are disengaged)

Going from High to Low:

- Open the lid to the headstock and the small cover on the side of the headstock near the chuck.

- Rotate the chuck until you see the locking pin come into view where you lifted the small cover.

- Grab the pin and pull it out and down. The chuck and pulleys should now be disengaged from each other.

- Engage the back gearing using the lever towards the back of the headstock on the left side.

- Close the lids. You're all done!

Aligning the tailstock

Using the powerfeed and gearbox

Using the halfnut and threading dial

Manuals

How to Run a Lathe - an old handbook with everything you need to know

Southbend -folder on the member google drive full of related documents

Helpful Videos

- Southbend Lathe Training Video

- Essential Machining Skills: Working with a Lathe

- Taper Attachment assembly

- Disassembly and explanation of the saddle, half-nut, and power feed

- Grinding HSS tools

- Using dial indicators

- Using calipers and micrometers

- Mini machinist mallet - video of a mallet lathe project (warning: sick metal music playing the whole time)

Stock materials

Important factors (machinability, hardness, material and cutter, maximum sizes)

Cold-rolled steel

Hot-rolled steel

Cast

Beginner Projects

- Machinist's Hammer - a project by Tim Nummy

- Whistle

- Storage Tube with hidden seam

- Spinning Top

- Decorative Ring

- Machinist Jack

- Chuck key

Tool bits and accessories

- Aloris BXA-style (200 series) quick-change toolpost with multiple tool holders

What we have for insert tool holders

- SHARS 1/2 X 4" RH MCLN INDEXABLE TURNING TOOL HOLDER CNMG

- MGEHR1616 Parting Off Turning Tool Holder

- Insert: MGMN200

- Anytime Tools 5 Piece 1/2" MINI LATHE INDEXABLE CARBIDE INSERT TOOL BIT SET - link

- Insert: TCMT 090204 - link

Where to buy

- AlexNLD - Toolholding - Inserts, tool holders, and more.

- MSC Direct - Tool Holding

- McMaster Carr - Everything, but also inserts and tool holders

- Ebay - Good ol' ebay, its got everything

- Amazon - Amazon also has everything