Difference between revisions of "CNC Milling Machine"

Jump to navigation

Jump to search

m (added links to guides, more detail on specs) |

|||

| Line 14: | Line 14: | ||

*Collet: R8 with a Kwik-Switch adapter | *Collet: R8 with a Kwik-Switch adapter | ||

*Control Software: Mach3 | *Control Software: Mach3 | ||

This is a precision tool and must be used with great care. | |||

If this machine is experiencing problems, please contact the Manager right away. | |||

=Guides and Manuals= | =Guides and Manuals= | ||

* | *[https://docs.google.com/document/d/1y5x75Bkry4B9mwGdyXs07dA2ijSdpyYk/edit?usp=sharing&ouid=117523248034611898107&rtpof=true&sd=true CNC Bridgeport Start Up Procedure] | ||

*[https://docs.google.com/document/d/1NN072pXqLhDPMkaGUxsTrScAEMOfwaX7H3DRI4zl_hY/edit?usp=sharing CNC Mill Technical Information] - A doc researching the part and components of the machine itself. | |||

==BRIDGEPORT DO’S AND DON’TS== | ==BRIDGEPORT DO’S AND DON’TS== | ||

Revision as of 11:46, 19 September 2024

THIS PAGE IS A WORK IN PROGRESS

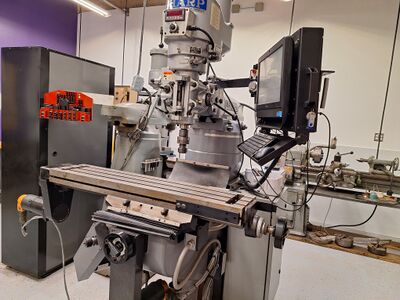

About our machine

- Model: M3X CNC

- Table:

- Length:

- Depth:

- Vertical movement:

- Motor: Skyey 220V 3PH 8A

- Collet: R8 with a Kwik-Switch adapter

- Control Software: Mach3

This is a precision tool and must be used with great care. If this machine is experiencing problems, please contact the Manager right away.

Guides and Manuals

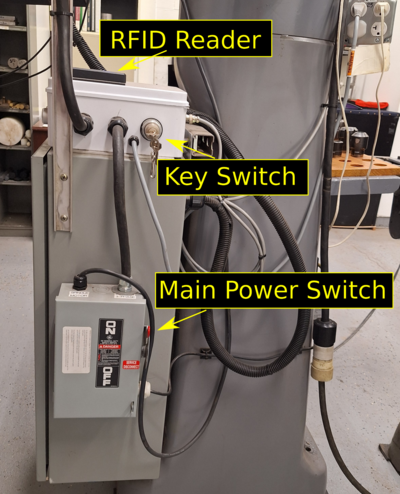

- CNC Bridgeport Start Up Procedure

- CNC Mill Technical Information - A doc researching the part and components of the machine itself.

BRIDGEPORT DO’S AND DON’TS

DO

- Ensure you have received training before performing an operation on this machine

- Use appropriate coolants and lubricants designed for machining

- Remove all tooling and extra fixtures used for your operations when you're done

- Check the collet and inside of spindle for loose chips to prevent damage to both

- Report any damage or broken tools right away so they can be fixed/replaced

DON’T

- Use water as a coolant without putting a rust-preventative in it like Kwikool

- Leave metal chips on the machine or on the floor

- Adjust or remove the vise, rotate the head, or modify the machine if you don’t know how the process to “tram” them back to square

- Forget to clean up and put tools back in their proper place

- Use endmills in the drill chuck

General Tips and Safety

- Wear safety glasses! Chips that come off are hot, and if your whole part comes off it will not be pretty.

- If you need a sharp endmill, you should have your own set. Our tools are shared use and are not always the sharpest.

- Clean and oil the machine's ways and surfaces when you are done

- DO NOT USED COMPRESSED AIR TO CLEAN

- DO NOT USE WATER AS A COOLANT. Water will rust the precision metal surfaces, making them not precision anymore. Use a rust-preventing additive like Kool Mist.

Tooling

Fixtures

Maintenance

Videos

Additional Reading

- M3X CNC Automation – see Artisian Asylum website: https://wiki.artisansasylum.com/wiki/M3X_CNC_Milling_Machine

- Bridgeport Sharp – possible manual: https://me.berkeley.edu/wp-content/uploads/2020/09/Sharp-Vertical-Mill-Manual.pdf

- Quill Feed Programming Manual (from Artisian Asylum website): CNC_Accupath_M3X_Operator_Programming_Guide.PDF (saved on downloads)